BASIS EP, power conversion solution provider.

Basis EP specialization relies on power conversion from few kilowatts to several tens of megawatts with international customers or major national laboratories. These activities require an important and active R & D departement and a constant renewal of technologies, both for control or power conversion.

Basis EP specialization relies on power conversion from few kilowatts to several tens of megawatts with international customers or major national laboratories. These activities require an important and active R & D departement and a constant renewal of technologies, both for control or power conversion.

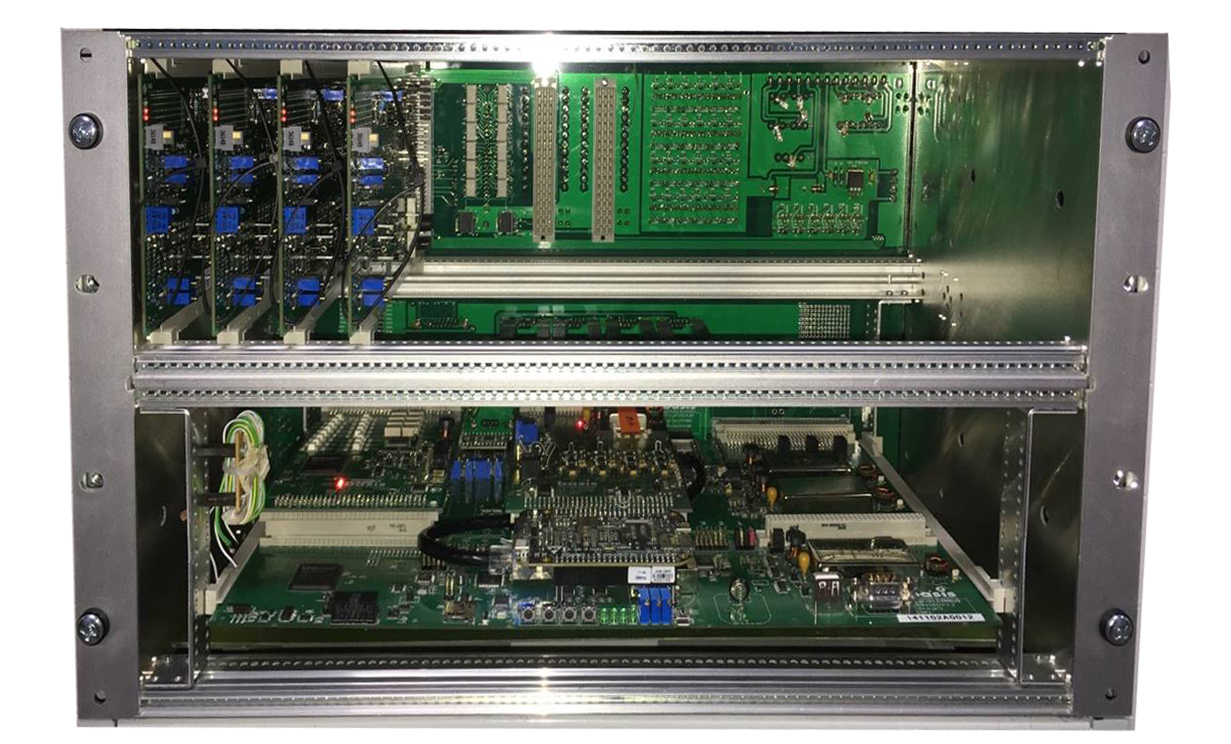

BASIS is composed of its workshop and its design department where electrotechnical, electronic, mechanical and software departments work together to achieve power converters projets.

Today, BASIS EP is also able to provide to customers and partners a reliable technical answers combining our knowledge to our client’s unique expertise in the following areas:

- For industry, with high current rectifiers for electrolysis. We implement diode or thyristor transfo-rectifier, as well as turnkey project with shelterized rectifier.

- For science, mainly for laboratory needs, especially for particles accelerators and to supply magnets for beamlines.

- For pulsed energy, from laboratories to industry, everywhere high density of energy is involved, especially on high voltage, for space applications, telecommunication or food industry.

- For Military field, any kind of electronic cabinet, for embedded equipment with high integration level or infrastructure facilities with shelterized converters.

Our History

Following its will to improve work, businesses and exchanges, BASIS EP differentiates itself thanks to its ability to be mobilized for its clients, always seeking the best in technical, technological and service matters.

BASIS EP is one of the leading French company in Power Electronic solutions as close as possible to its clients’ needs, to stand by them from the conception to the commissioning in their conversion projects.

BASIS EP confirm its will to share its fundamental values which are the satisfaction and respect of the commitments made to its customers, its employees, and its suppliers.

Know-how

BASIS EP develops its know-how in producing converters and rectifiers to implement solutions in power conversion with:

- SCR, thyristors and diodes for power rectifiers and rectiformers.

- IGBT bridges for Buck, Boost converters, switching mode for high voltage or low voltage converters

- Specific transformers (LV/HV), 50/60Hz or high frequencies or multi secondary windings

- HV switchboards

- shelterization or maritim container modifications for integration in specific environment.

- Coils and capacitors, high performance filters

- Busducts, copper or aluminium busbars

- Systems instrumentation

- Analog or digital regulation for converter drives

Based on its high level engineering department, BASIS EP offers ability to innovate in order to break down technological barriers to meet customer requirements, and offers solutions in power conversion for better reliability, robustness and a high level performance.

R&D Partnerships with academic institutions, laboratories or even R&D partners’ departments are established, to innovate through research programs on topics related to customer issues.

The expertise of BASIS EP is deployed around :

- Specific project management or engineering services on major projects

- Turnkey Projects (Civil Engineering, HV Distribution, Energy Conversion, DC busduct)

- Retrofit or refurbishment of converters

- Maintenance on any brand of rectifier

- Upgrade of control command or regulation units

- Eco design

BASIS EP adapts to the client’s needs, its team being pleased to adapt design.

Quality

In order to internally control all actions undertaken within the frame of our business, the CEO set up a Quality Management Plan.

The full implementation of the processes related to ISO9001-2015 is thus deployed and BASIS EP applies such principles and processes to each project.

– A commercial process to support customers very far far upstream of project, on specification stage, with checking compliance matrix and being proactive during the proposal stage to offer a solution adapted to the just need.

– A project process starting with engineering phase:

- Electronics

- Electrical and electrotechnical

- Mechanical

- Cooling (water or air)

- Network analyses

- safety studies

- FMEA

Then production and testing phase:

- 1200 m² workshop

- Manufacturing and testing control procedures

- Testing plans

- 300kVA platform test with test facilities.

Finally, a process for after-sales and maintenance

- Installation of equipment on site

- Preventive maintenance

- Curative maintenance

- Configuration management procedures

- Technological watch

- Obsolescence management

- Training